Software

WinPC-Nc

Tinkercad

Fusion 360

We used soap to make our positive for the molding because soap is cheap to buy and also easy to cut.

Group assignment(Read more aboutthe group assignment.)

Invidual assignment : design a mold around the stock and tooling that you'll be using, mill it (rough cut + (at least) three-axis finish cut),and use it to cast parts as a invidual assignment.

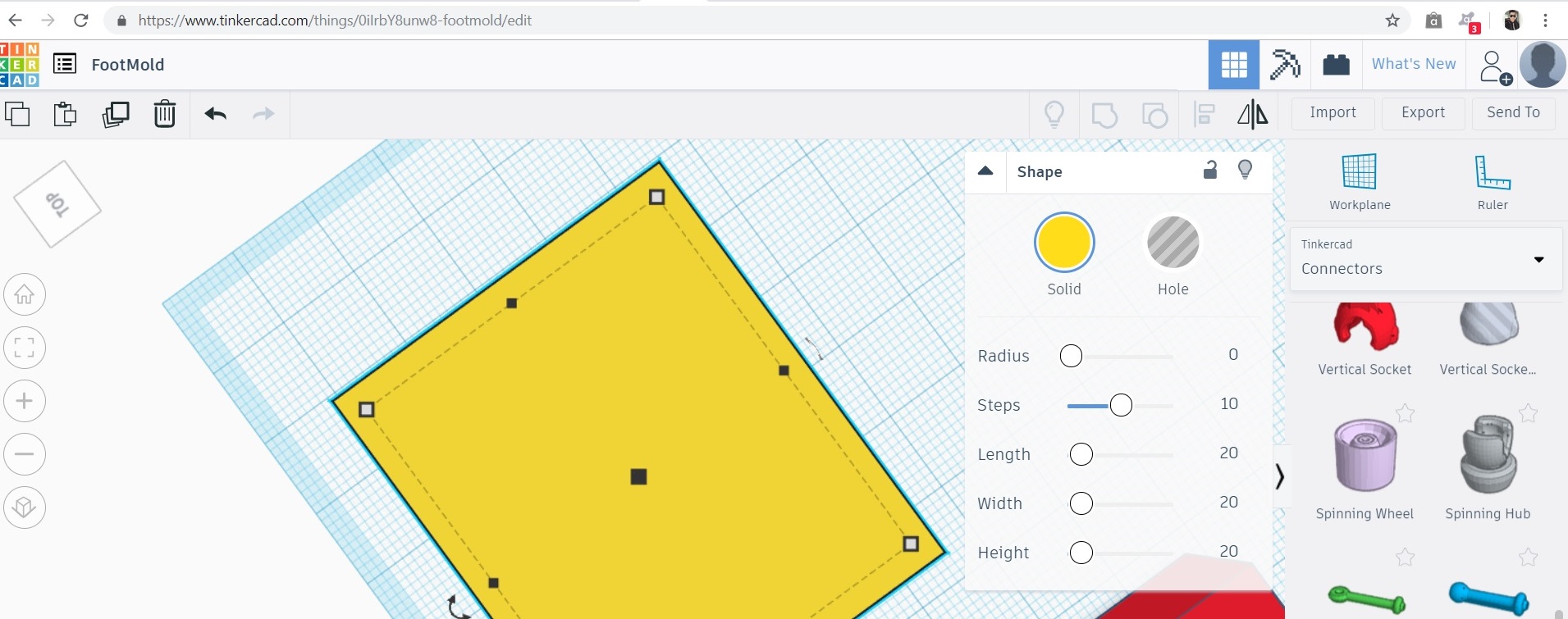

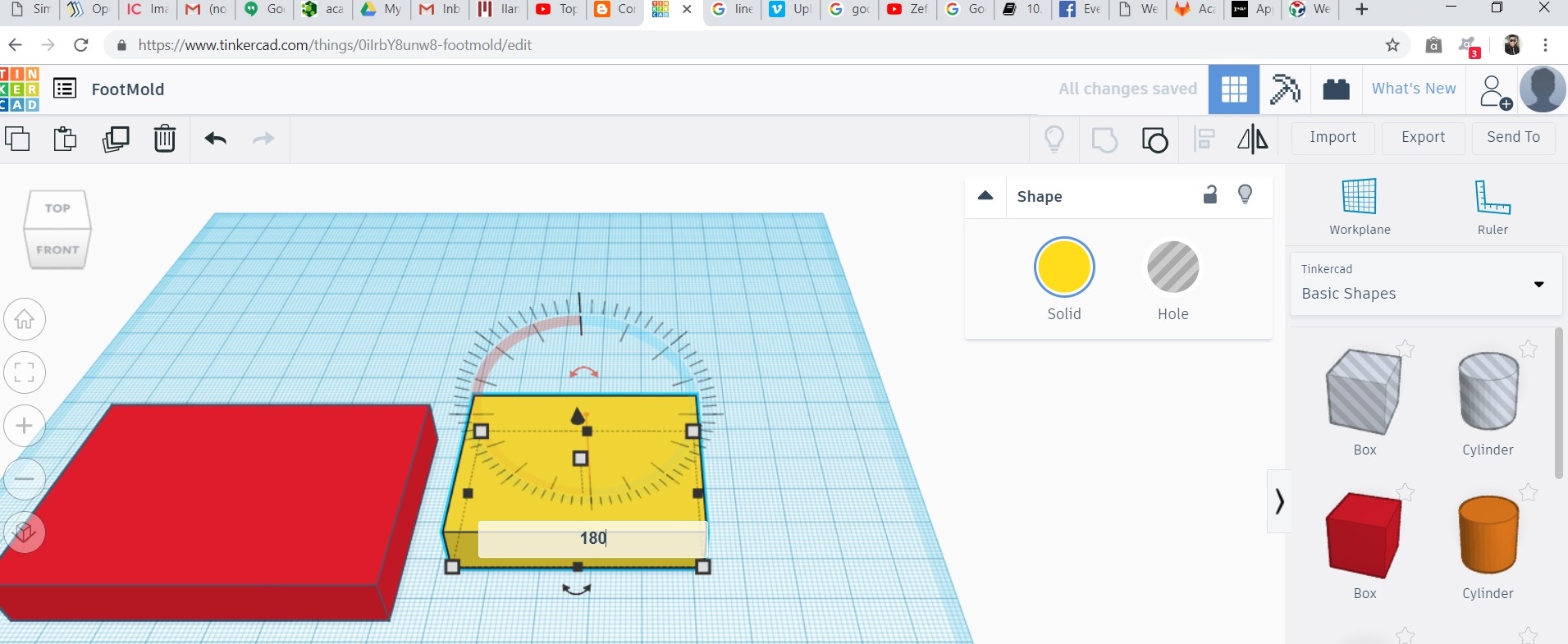

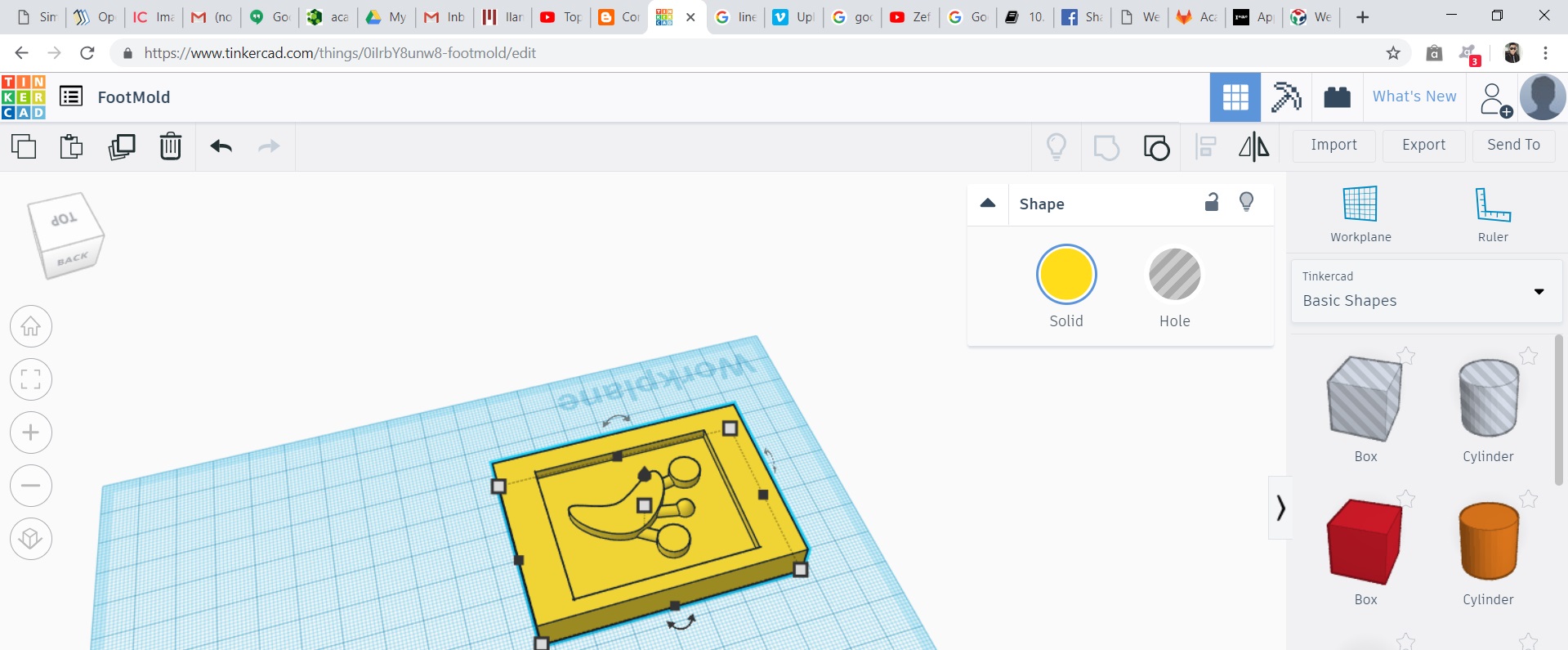

Tinkercad design

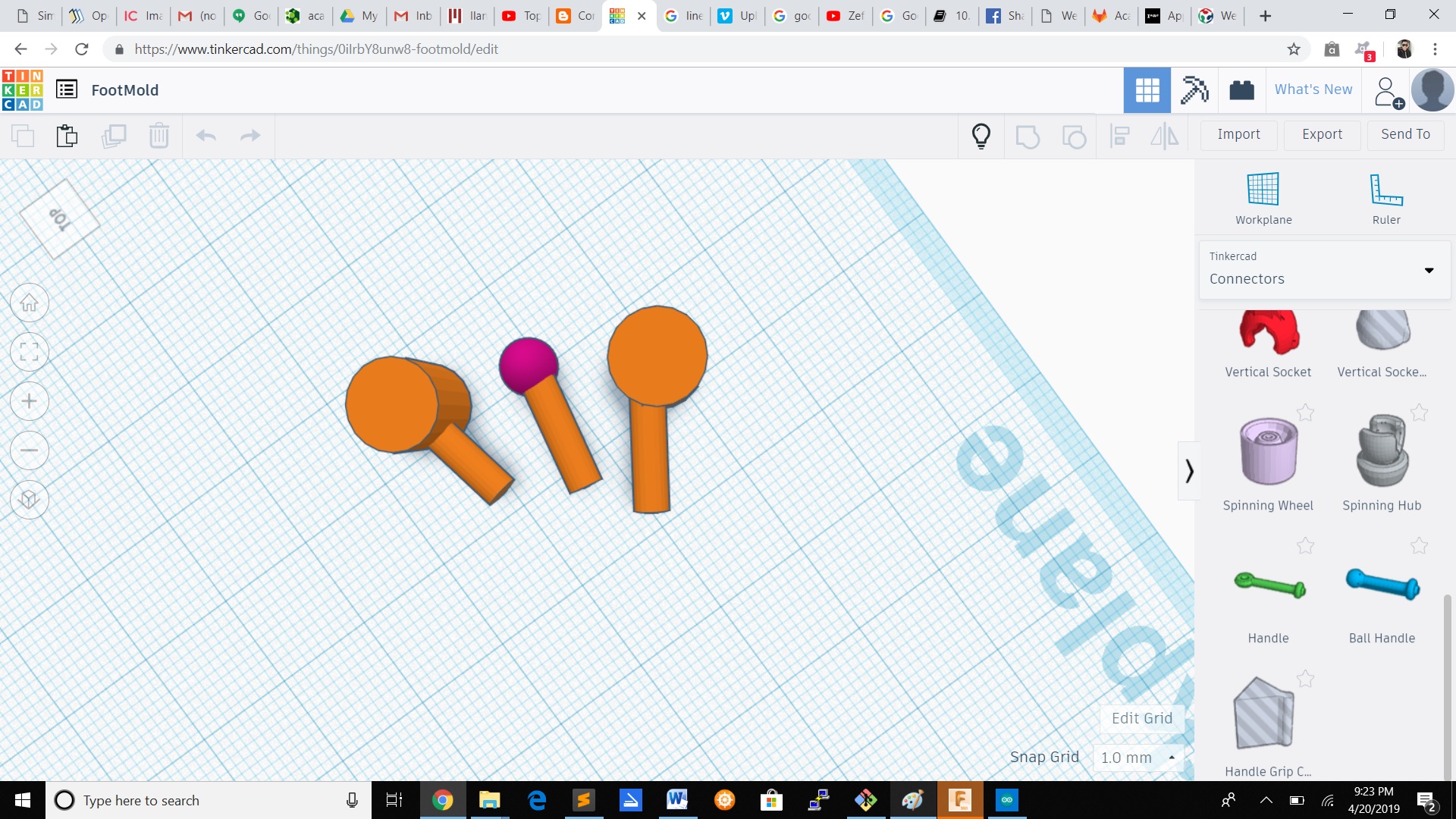

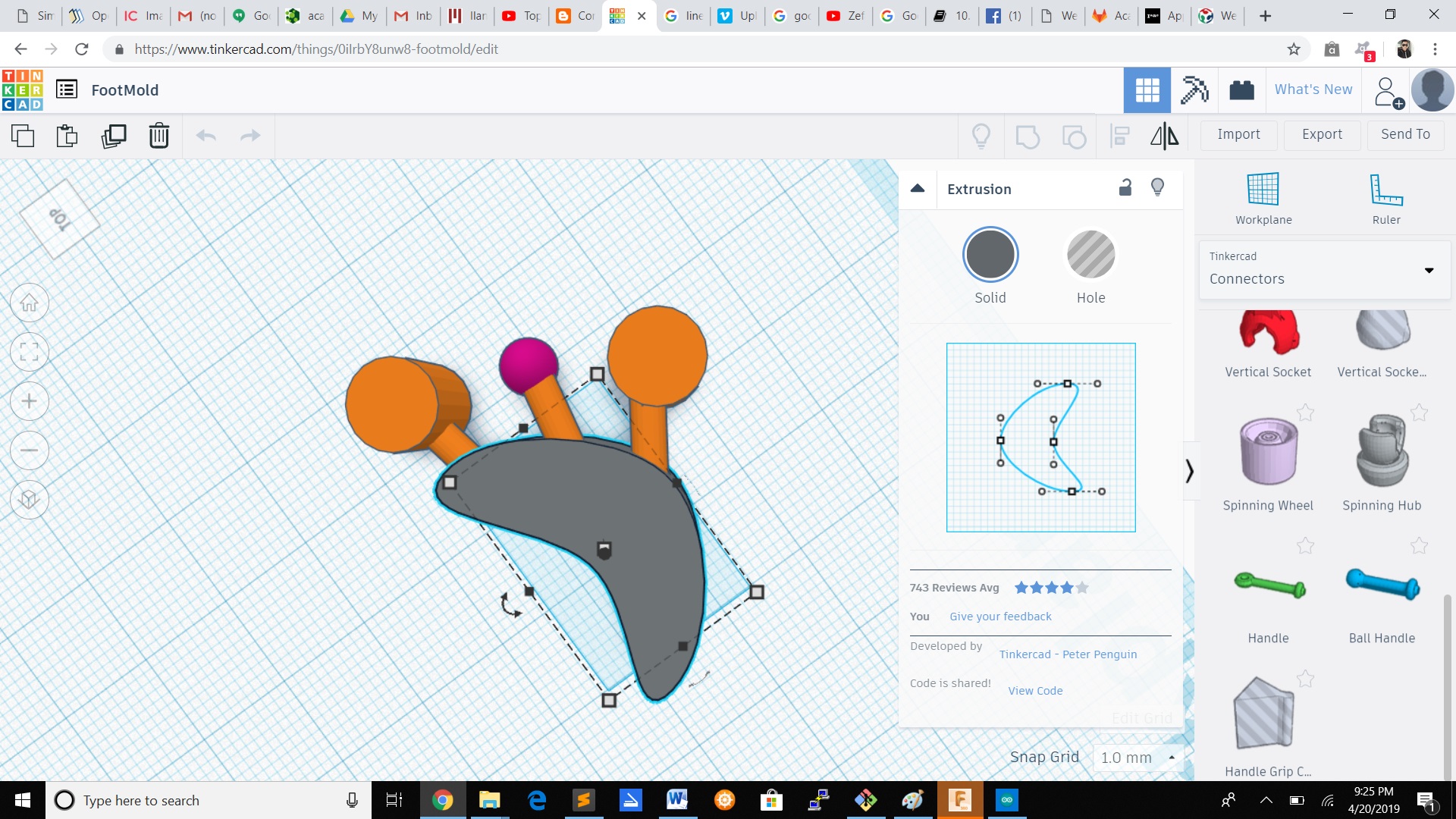

I made my design in Tinkercad and i made a foot with two shapes of toes.The middle toe has the kerf that the design suppose to have.Save my design in .STL format and then imported my file in Fusion 360 to add the parameters for cutting my design.

This Design has:

1.Cylinder

2.Half Sphere

3.Ball Handle

4.Extrusion

5.Box

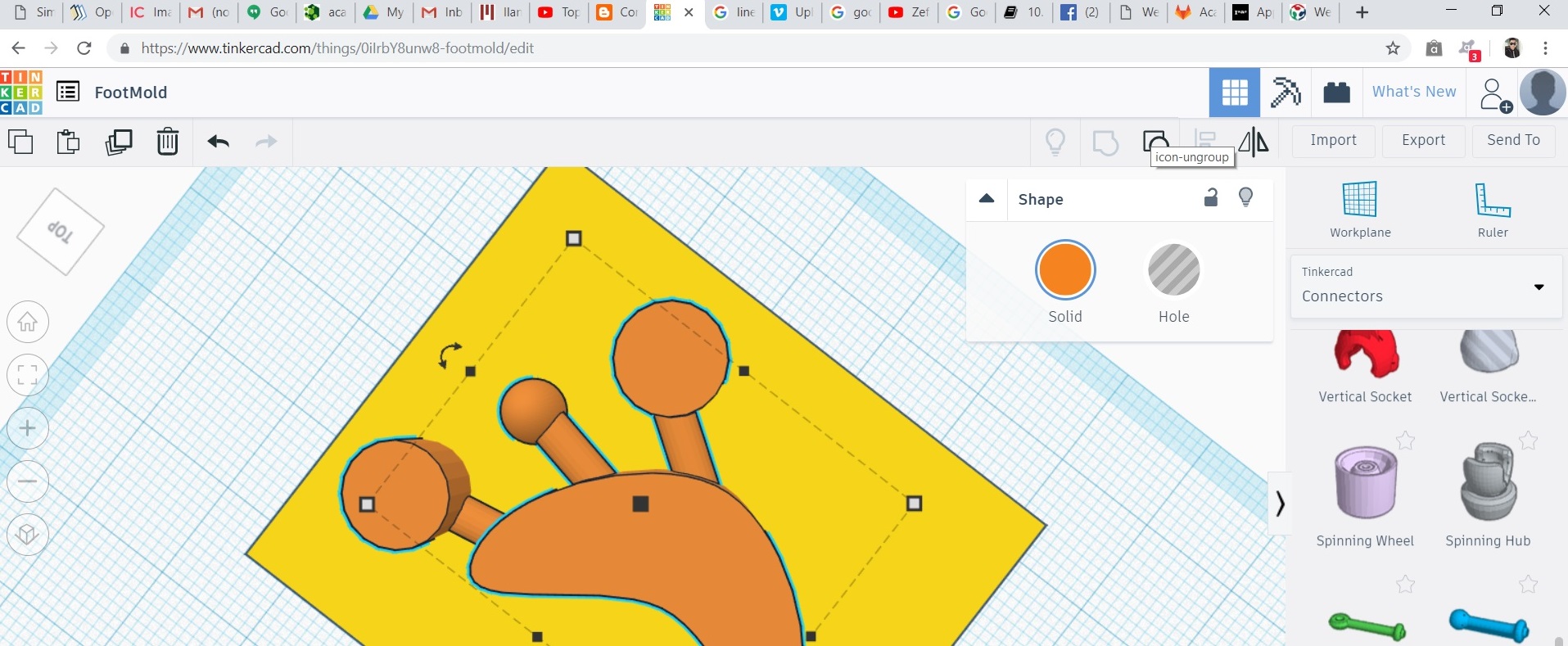

Select the half sphere,the cylinder and the ball handle to get the toes for the foot.

Select the extrusion and form the other part of the foot.After doing that group all shapes to make them one body.

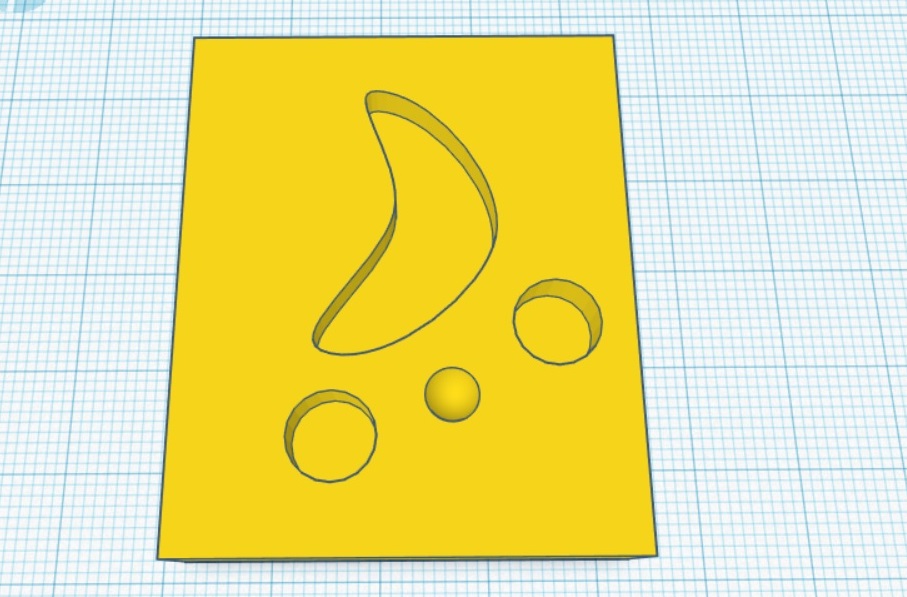

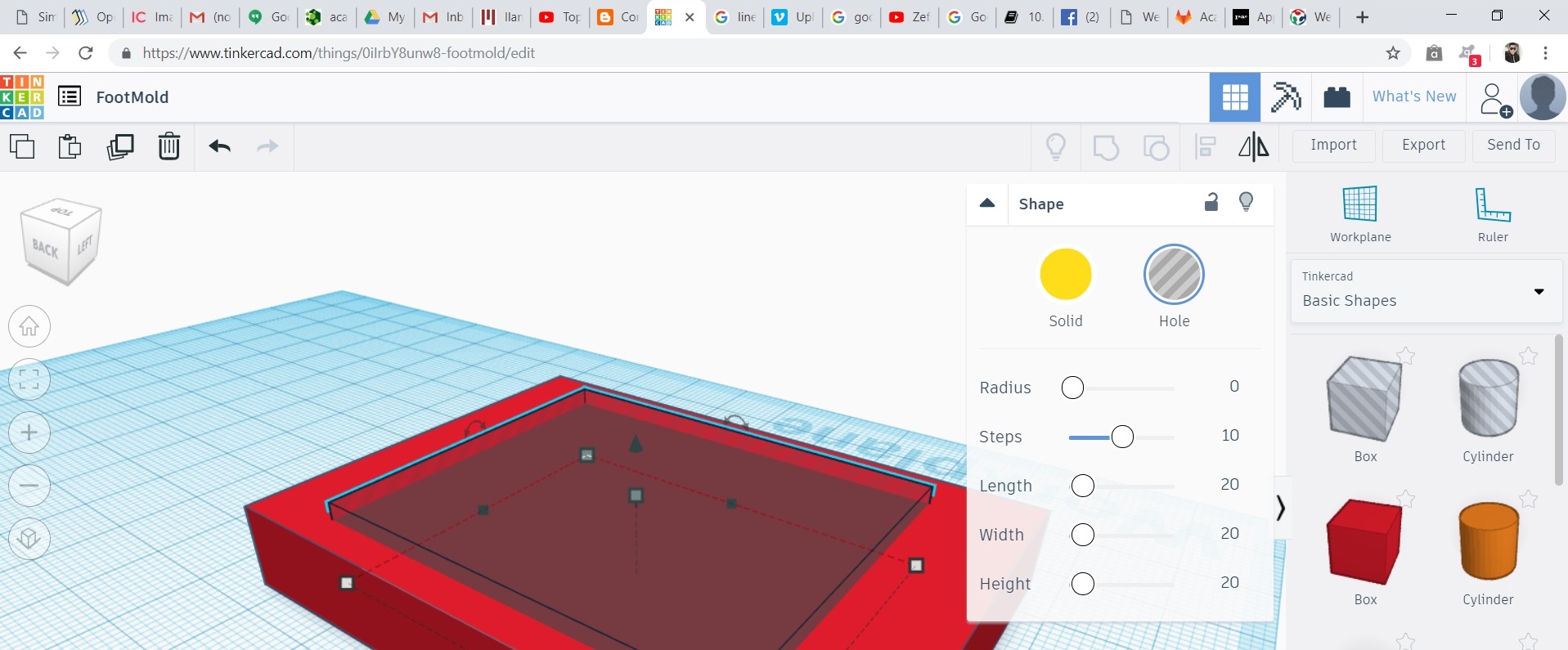

Select a box and make it to place the foot in it to get the form.

After placing the foot in the box and click on hole.

After doing that select the two shapes and then group them.

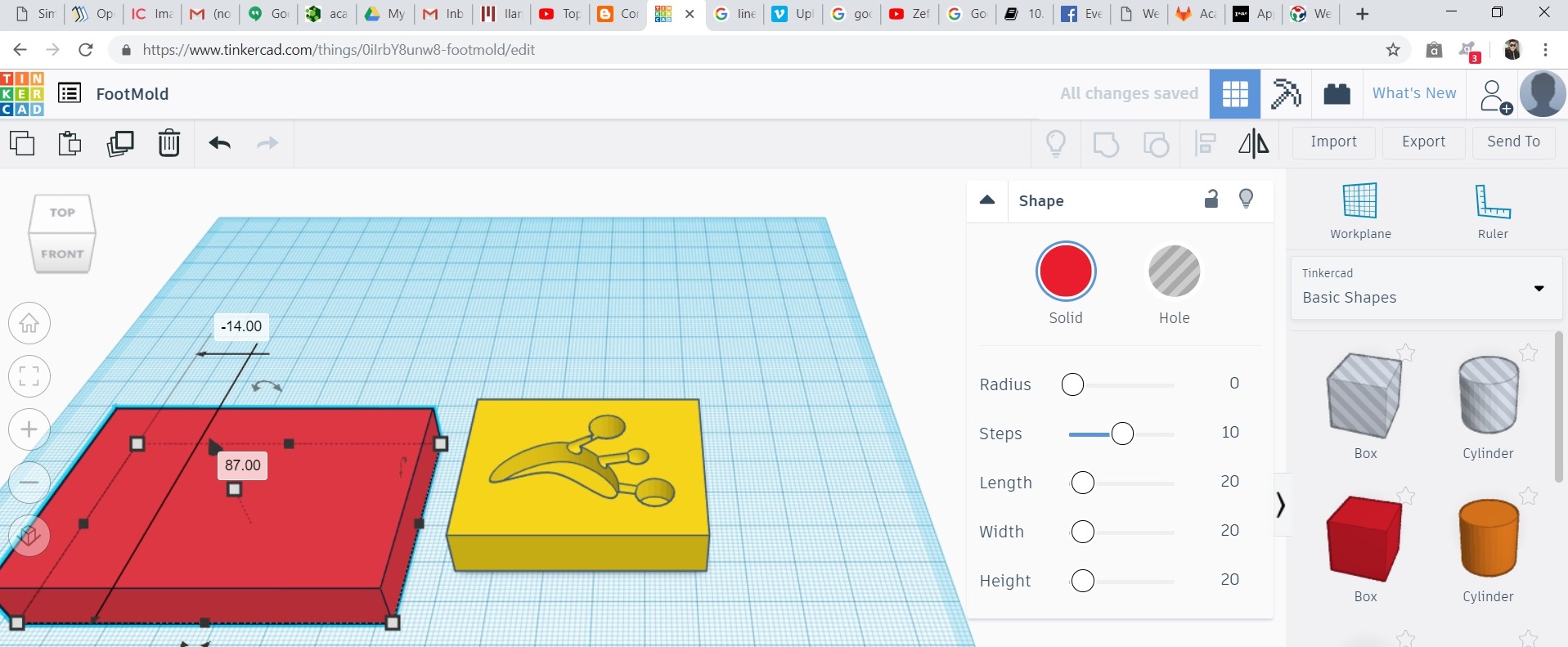

Select another box and make it bigger then the previous one.

Rotate your design 180 degree and place it on the box.

After putting it on the box ,click on hole and then you will get theform in the box.

Here you have the design of the mold

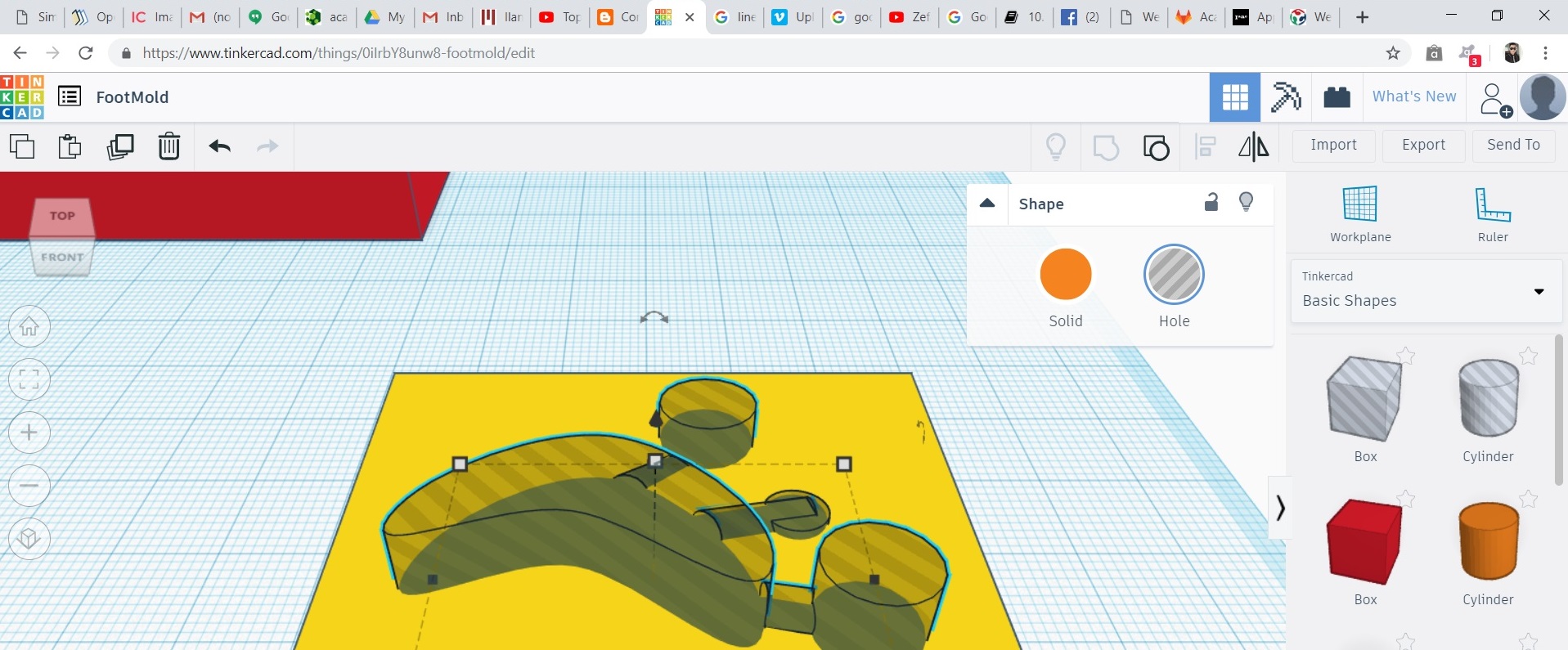

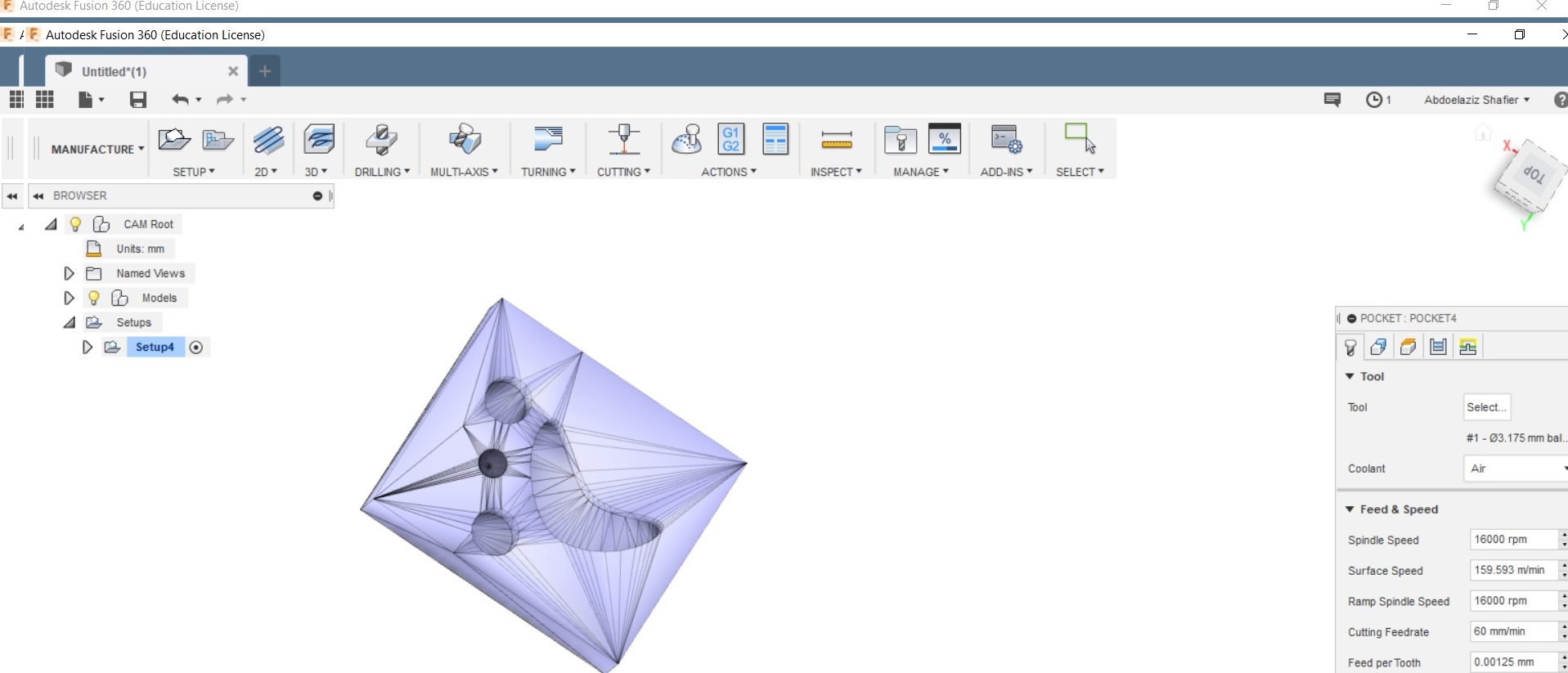

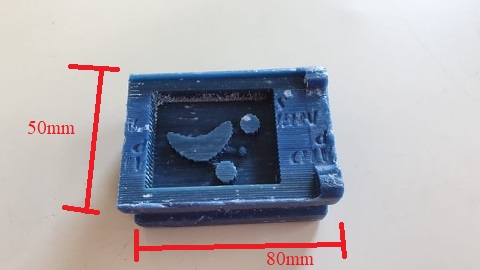

After importing my file into fusion,you have to check if your design has the same size like the size you gave it in Tinkercad.If you are working with a soap with a special size,you have to make your design that fit in that special size soap.

The soap size i used is 80mm width and 50mm height and the depth is 35mm.So i scaled my design to fit in the size of the soap.

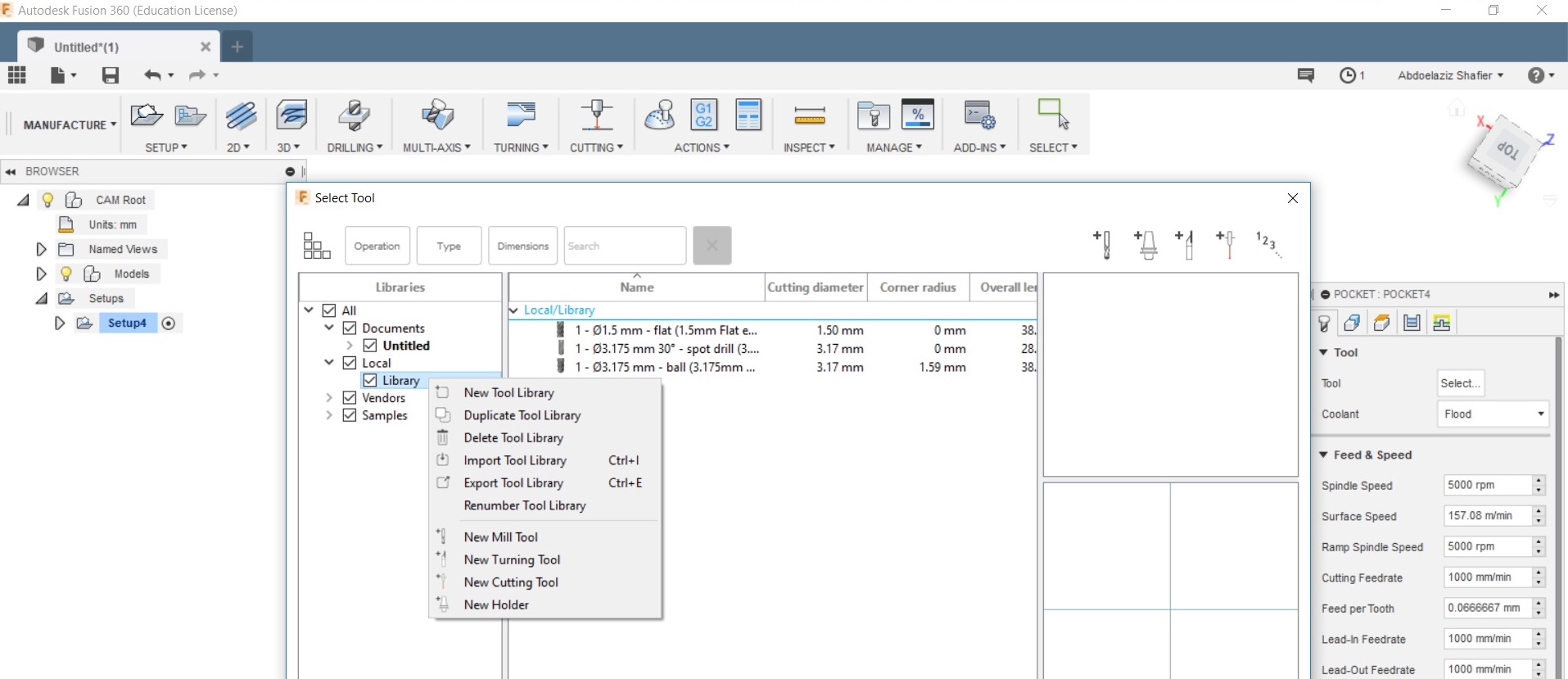

If the mill you're going to use is not in the library,you have to add the library.For the pocket cutting i used the 1/8" flat endmill and for the parallel cutting i used the 1/16" ball endmill.For using the milling machine i added parameters for cutting the soap.I have selected for pocket and also parallel.Pocket means that it wil cut on the inside of the soap and Parallel means that it will cut parallel lines on the soap.

Pocket Parameters :

| Parameter | Value |

|---|---|

| spindle speed | 16000 rpm |

| cutting feedrate | 1000mm/min |

| Feed per tooth | 0.03 mm |

| Plunge feedrate | 762 mm/min |

Parallel Parameters :

| Parameter | Value |

|---|---|

| spindle speed | 16000 rpm |

| cutting feedrate | 1000mm/min |

| Feed per tooth | 0.03 mm |

| Plunge feedrate | 762 mm/min |

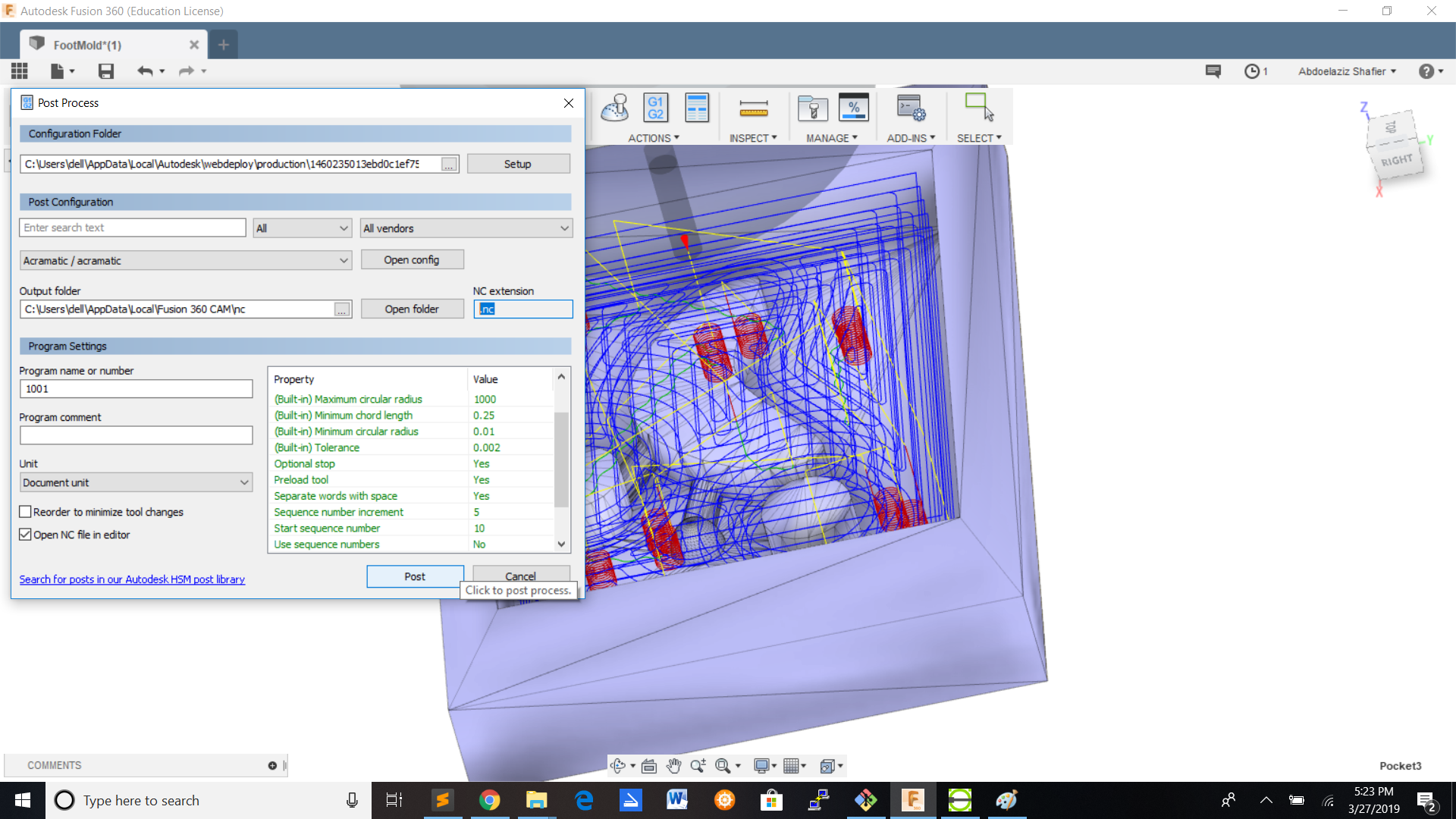

To make the parameters in fusion work on the stepcraft milling machine,we downloaded the winpc.nc.cps file so that we can save the design in .nc format and use it on the stepcraft milling machine.

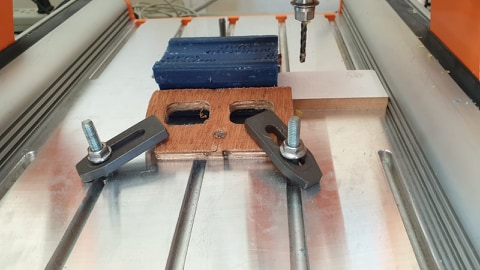

Before you begin to mill make sure your object fasten to the board.

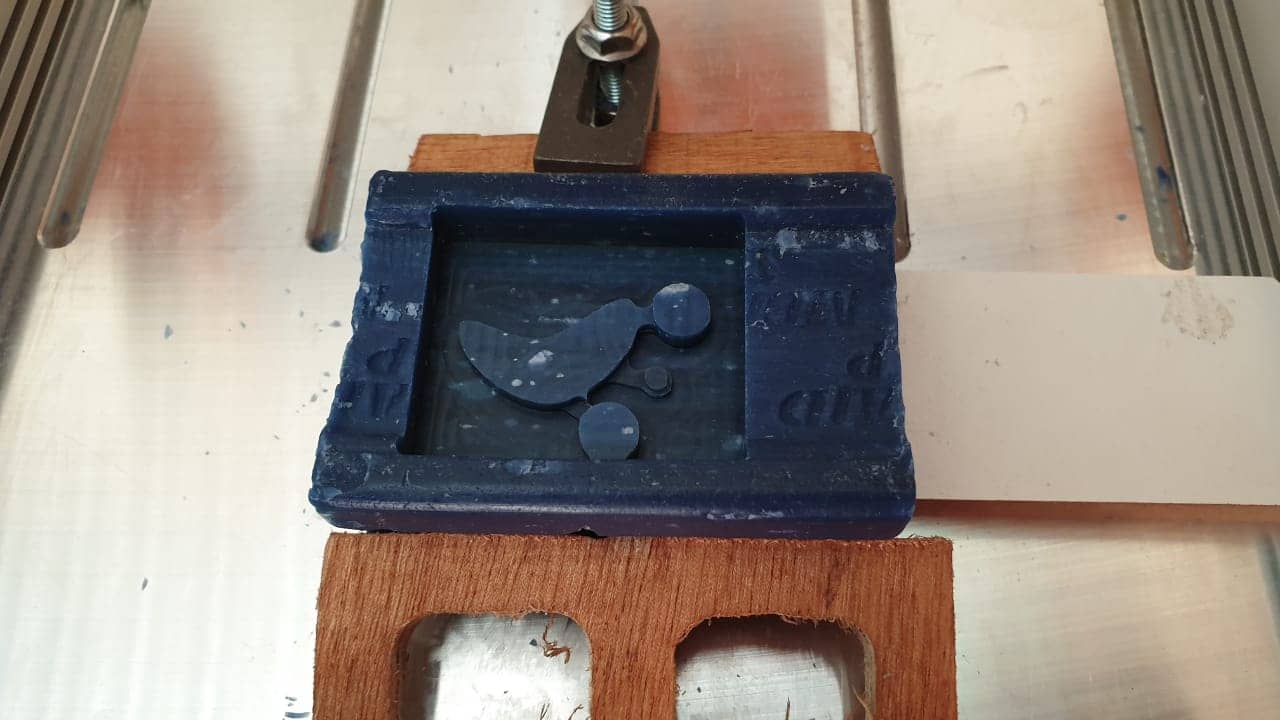

Pocket milling using soap and this is the outcome

Parallel milling using soap and this is the outcome

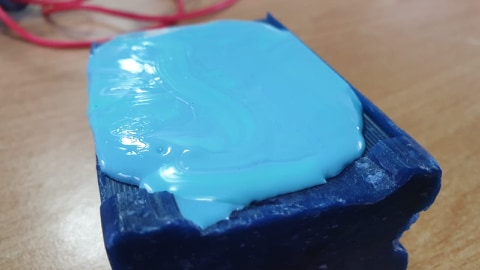

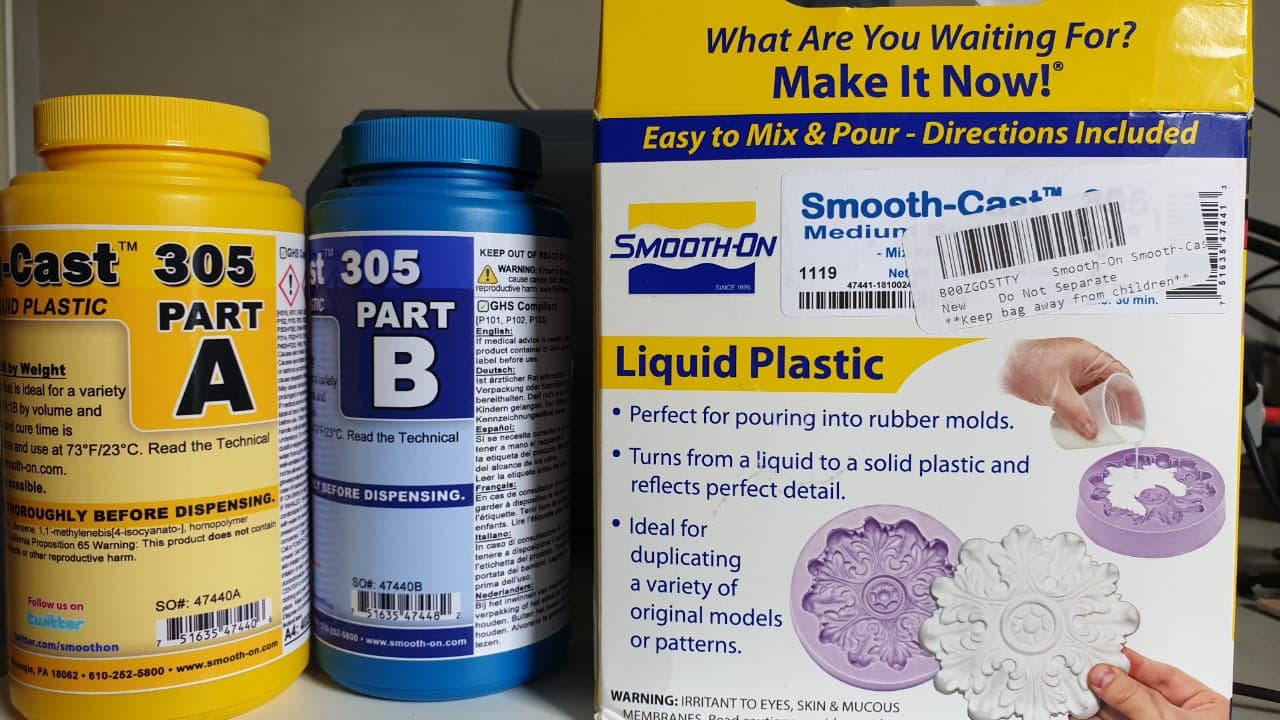

For the rubber you have to mix liqued a and liquid b together and you have to stir it wel.If it isn't stir wel you will get holes in the rubber.After stiring it you have to let it dry.I left mine 12 hours to dry.We didn't have the rubber liquid in the first time so we tried silicone to look if it works and it didn't came good.

Putting the mix into the design.

The mold should be like this.

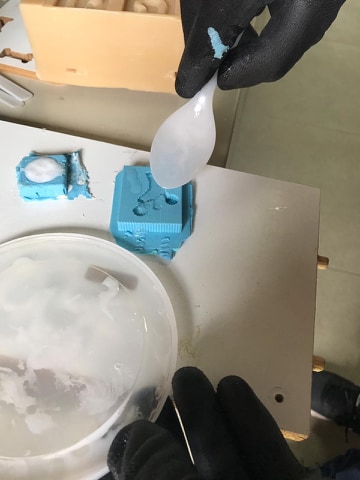

For the cast you have to mix liquid a and liquid b together and you have to stir it wel.If it isn't stir wel you will get holes in the rubber.After stiring it you have to let it dry.I left it for 24 hours.

After letting it dry the cast should look like this.

Files

Footmold FusionFinish cut

Rough cut

Footmold tinkercad